LOADING...

Industry 4.0

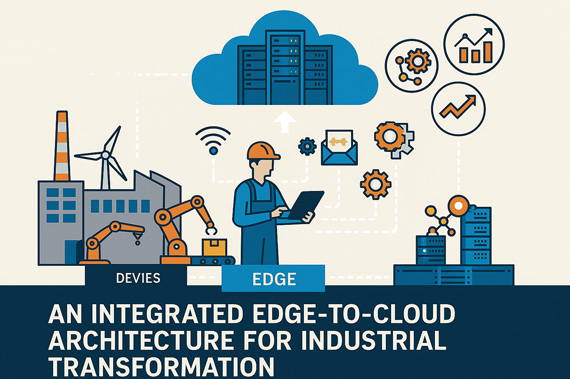

An Integrated Edge-to-Cloud Architecture for Industrial Transformation

Tanos is engineered to serve as the foundational infrastructure for smart industrial ecosystems. Our platform facilitates the deployment of Industry 4.0 by combining robust field automation with edge computing and cloud-native analytics. Designed to modernize both greenfield and brownfield facilities, Tanos provides a unified platform that delivers real-time operational visibility, autonomous control logic, advanced diagnostics, and centralized remote management. This architecture is particularly valuable for organizations looking to modernize legacy OT systems without sacrificing reliability or control.

What is Industry 4.0—Beyond the Buzzwords?

Industry 4.0 represents the digital convergence of physical industrial systems with information and communication technologies. It is not merely about automation but about creating intelligent systems that continuously adapt and improve using data. Industry 4.0 involves the integration of sensor-rich environments, edge-based computation, real-time data streaming, and cloud-based decision support. Tanos enables this vision by offering a platform that spans the entire technology stack—from programmable logic controllers (PLCs) at the edge to cloud-hosted dashboards and AI-driven analytics.

Edge-Driven Data Acquisition

At the device level, Tanos supports all major industrial communication protocols, including Modbus RTU/TCP, BACnet/IP, OPC-UA, and MQTT. This makes it highly adaptable to existing field assets without requiring costly retrofits. The system is capable of ingesting data from a wide array of sensors, including those monitoring temperature, pressure, flow, vibration, RPM, IAQ, water levels, and energy consumption. Additionally, edge logic modules allow for the deployment of automation routines directly on-site—enabling control of pumps, air handling units (AHUs), chillers, valves, and actuators with real-time response.

Integrated Edge Gateway & Historian

TanosEdge™ serves as the local processing layer, equipped with Linux-based ARM processors that collect, pre-process, and store data locally in time-series databases. This ensures deterministic behavior and resilience in case of network disruption. Our system features real-time filtering algorithms and pattern recognition routines that highlight anomalies before they become faults. Trend buffering at the edge ensures high-resolution data is preserved and securely synchronized to the cloud when connectivity is restored.

Cloud-Native Industrial Data Platform

Tanos securely transmits operational data to the cloud using encrypted communication channels. Our backend infrastructure uses resilient data stores such as InfluxDB, TimescaleDB, and S3-compatible buckets to handle millions of events daily. It features role-based access control, tamper-resistant logging, and compliance with global standards like ISO 27001 and GDPR. The platform is built with horizontal scalability in mind, enabling you to manage assets across hundreds of geographically distributed locations with a unified interface.

Contextual Analytics & Operational Intelligence

Once data is contextualized in the cloud, users gain access to intuitive dashboards that provide plant managers, facility teams, and executives with actionable insights. Dashboards display key metrics such as air quality indices, pump efficiency, motor health, energy usage, water consumption, and deviation trends. Advanced modules also offer condition-based maintenance recommendations, FMECA (Failure Modes, Effects and Criticality Analysis) scoring, and equipment health indices. Tanos can integrate seamlessly with enterprise systems like SAP, IBM Maximo, and Oracle Fusion through REST APIs, ensuring contextual insights flow into your broader operational workflows.

Centralized Control & Command Center (CCC)

Tanos-powered CCCs serve as nerve centers for modern industrial environments. Designed for large-screen or multi-screen setups, these centers allow for real-time monitoring and control across various infrastructure components—including building management systems (BMS), fire panels, water pumps, diesel generators, and chillers. The CCC interface features real-time alerts, customizable workflows, audit trails, and escalation matrices. With map-based plant navigation and drill-down capability, users can quickly pinpoint issues by zone, asset type, or system layer.